Moscardinia, M., Gan, Y., Annabattula, R.K., Kamlah M. (2017) A Discrete Element Method to simulate the mechanical behavior of ellipsoidal particles for a fusion breeding blanket. Fusion Engineering and Design. 121: 22-31.

[DOI][PDF:046_FED_2017_M]

Abstract:

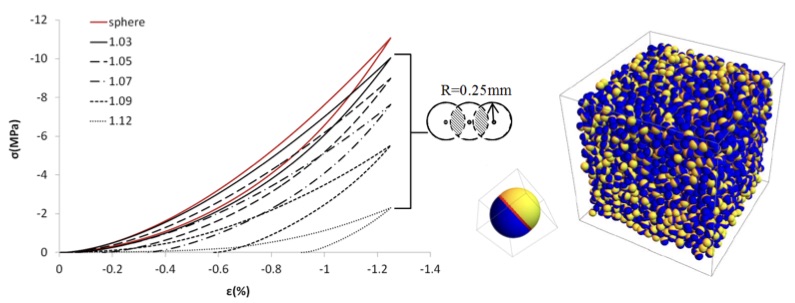

The breeder materials proposed for the solid tritium breeding blanket concepts are ceramic lithium-based compounds in the form of pebble beds. Different fabrication processes have been developed to produce pebbles with a high sphericity. However, a small deviation from a perfectly spherical shape exists. In this paper the influence of non-sphericity on the mechanical behaviour of a pebble bed is assessed representing the currently produced pebbles by means of ellipsoidal particles. To this end, the in-house Discrete Element Method code KIT-DEM was further extended. The multi-sphere approach was implemented to generate the ellipsoidal particles while the existing random close packing algorithm was modified to create the assemblies. Uniaxial compression of the assemblies, under periodic boundary conditions, was simulated to investigate the bulk stress-strain behaviour of the bed. Sensitivity studies were carried out with different packing factors of the assembly and several aspect ratios of the particles. In agreement with previous studies carried on assemblies of spherical pebbles, the initial packing factor was found to noticeably affect the mechanical response of the investigated assemblies. Moreover, a remarkable influence of the shape on the mechanical behavior of the simulated assemblies was observed. Therefore it is concluded that for production techniques that result in poor sphericity, DEM simulations with non-spherical particles are necessary to reproduce realistic stress-strain behavior of pebble beds.

Keywords: Discrete element method; Pebble bed thermomechanics; Nuclear fusion; Multi-sphere approach; Ellipsoidal particles

Full paper can be downloaded via Publications page.

Leave a Reply